| Function | Shortcut Key |

| Show Shortcut Keys | Ctrl + K |

| Enter Query | F11 |

| Execute Query | Ctrl + F11 |

| Count Query | F12 |

| Clear Block | F7 |

| Clear Field | F5 |

| Clear Form | F8 |

| Clear Record | F6 |

| Edit | Ctrl + E |

| Update Record | Ctrl + U |

| Insert Record | Ctrl + Down |

| Delete Record | Ctrl + Up |

| Commit | Ctrl + S |

| Duplicate Field | Shift + F5 |

| Duplicate Record | Shift + F6 |

| List of values | Ctrl + L |

| List Tab Pages | F2 |

| Next Field | Tab |

| Next Record | Down Arrow Key |

| Next Primary | Key Shift + F7 |

| Next Set of Records | Shift + F8 |

| Previous Field | Shift + Tab |

| Previous Record | Up Arrow Key |

| Previous Block | Shift+PageUp |

| Scroll Down | PageDown |

| Scroll Up | PageUp |

| Up | Up Arrow Key |

| Down | Down Arrow Key |

| Ctrl + P | |

| Exit | F4 |

| Help | Ctrl + H |

| Block Menu | Ctrl + B |

| Display Error | Shift + Ctrl + E |

Monday, 24 August 2015

How to enable shortcut keys in oracle apps

Friday, 21 August 2015

O2C full cycle in oracle R12

Following are the steps the process will go through from creating a Sales Order to Posting the details in GL.

· Enter the Sales Order

· Book the Sales Order

· Launch Pick Release

· Ship Confirm

· Create Invoice

· Create the Receipts either manually or using Auto Lockbox ( In this article we will concentrate on Manual creation)

· Transfer to General Ledger

· Journal Import

· Posting

Involved Modules

Order Management: Creating and shipping the Order

Inventory: Onhand availability, Reservation

Receivables: For Receipt against invoice

General Ledger: Importing, entering and posting the journals.Enter the Sales Order:

Order Management Super User Operations (USA)>Orders Returns >Sales Orders

Enter the Customer details (Ship to and Bill to address), Order type.

Click on Lines Tab. Enter the Item to be ordered and the quantity required

Save the work.

Then select Execute Now button.

Click on Lines Tab. Enter the Item to be ordered and the quantity required

Line is scheduled automatically when the Line Item is saved.

Scheduling/unscheduling can be done manually by selecting Schedule/Un schedule from the Actions Menu.

You can check if the item to be ordered is available in the Inventory by clicking on Availability Button.Save the work.

Tables Affected:

OE_ORDER_HEADERS_ALL

OE_ORDER_LINES_ALL

Columns used for identification of flow

FLOW_STATUS_CODE in both the tables which is ENTERED.

Book the Sales Order

Book the Order by clicking on the Book Order button

Now that the Order is BOOKED, the status on the header is change accordingly.

Tables affected:

The FLOW_STATUS_CODE in the table OE_ORDER_HEADERS_ALL would be BOOKED.

The FLOW_STATUS_CODE in OE_ORDER_LINES_ALL will be AWAITING_SHIPPING.

New records will be created in WSH_DELIVERY_DETAILS with RELEASED_STATUS=’R’ (Ready to Release)

Also Record(s) will be inserted into WSH_DELIVERY_ASSIGNMENTS

At the same time DEMAND INTERFACE PROGRAM runs in the background and inserts into MTL_DEMAND.

Launch Pick Release

Shipping > Release Sales Order > Release Sales Orders

Give the Sales Order and Rule details as required

Key in the details in Shipping Tab, Autocreate Delivery: Yes, Auto Pick Confirm: Yes, Autopack Delivery: Yes

Similarly key in the Subinventory, location and org details in Inventory tab as required

Pick Release process will in turn run few more concurrent requests like

Auto Pack Report,

Pick Slip Report, Shipping Exceptions Report (These are what we have

chosen in the shipping tab during Pick Release)

Tables Affected

If Autocreate Delivery is set to ‘Yes’ then a new record is created in the table WSH_NEW_DELIVERIES

DELIVERY_ID is populated in the table WSH_DELIVERY_ASSIGNMENTS

The

RELEASED_STATUS in WSH_DELIVERY_DETAILS would be now set to ‘Y’ (Pick

Confirmed) if Auto Pick Confirm is set to Yes otherwise RELEASED_STATUS

is ‘S’ (Release to Warehouse)

Pick Confirm the Order:

If Auto Pick Confirm is set to Yes during Pick Release, then this process will happen systematically.

In other cases, need to do this by doing a move order transaction

Inventory Super User > Move Order> Transact Move Order

Take the Move Order Number form the Shipping Transaction Form and find that and transact.

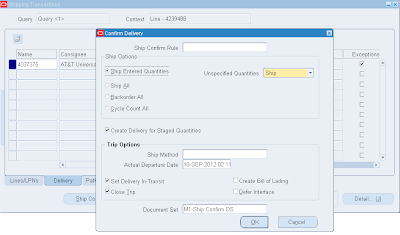

Ship Confirm the Order:

Order Management Super User>Shipping >Transactions

Find by Order Number

Here you can find all the details

If the line status is Staged/Pick Confirmed, we can go for a shipment

Then Click on the Delivery tab

Then Click Ship Confirm

Note: If Ship

Confirm button is inactive, then please check to the user id you are

logged in, whether Shipping Grant given or not. If not they add a

shipping grant to the user id and try again.

Then OK.

The Status in Shipping Transaction form in Delivery tab should be closed

This will kick off concurrent programs like.INTERFACE TRIP Stop, Commercial Invoice, Packing Slip Report, Bill of Lading

Tables Affected:

RELEASED_STATUS in WSH_DELIVERY_DETAILS would be ‘C’ (Ship Confirmed)

FLOW_STATUS_CODE in OE_ORDER_HEADERS_ALL would be “BOOKED“

FLOW_STATUS_CODE in OE_ORDER_LINES_ALL would be “SHIPPED“

Once all background process completes, the Shipping Transaction Status in Lines/LPNs tab becomes Interfaced

Create Invoice:

Run workflow background Process

Order Management >view >Requests

Workflow Background Process inserts the records RA_INTERFACE_LINES_ALL with

INTERFACE_LINE_CONTEXT = ’ORDER ENTRY’

INTERFACE_LINE_ATTRIBUTE1= Order_number

INTERFACE_LINE_ATTRIBUTE3= Delivery_id

And spawns Auto invoice Master Program and Auto invoice import program which creates Invoice for that particular Order

Check the Invoice:

The Invoice created can be seen using the Receivables responsibility

Receivables Super User> Transactions> Transactions

Query with the Order Number as Reference

Affected Tables:

RA_CUSTOMER_TRX_ALL

will have the Invoice header information. The column

INTERFACE_HEADER_ATTRIBUTE1 will have the Order Number.

RA_CUSTOMER_TRX_LINES_ALL

will have the Invoice lines information. The column

INTERFACE_LINE_ATTRIBUTE1 will have the Order Number.

Create receipt:

Receivables> Receipts> Receipts

Tables affected:

AR_CASH_RECEIPTS_ALL

Transfer to General Ledger:

To transfer the Receivables accounting information to general ledger, run General Ledger Transfer Program

Receivables> View Requests

Parameters:

- Give in the Start date and Post through date to specify the date range of the transactions to be transferred.

- Specify the GL Posted Date, defaults to SYSDATE.

- Post in summary: This controls how Receivables creates journal entries for your transactions in the interface table. If you select ‘No’, then the General Ledger Interface program creates at least one journal entry in the interface table for each transaction in your posting submission. If you select ‘Yes’, then the program creates one journal entry for each general ledger account.

- If the Parameter Run Journal Import is set to ‘Yes’, the journal import program is kicked off automatically which transfers journal entries from the interface table to General Ledger, otherwise follow the topic Journal Import to import the journals to General Ledger manually.

GL_INTERFACE

Journal Import:

To transfer the

data from General Ledger Interface table to General Ledger, run the

Journal Import program from Oracle General Ledger.

General Ledger > Journal> Import> Run

Parameters:

- Select the appropriate Source.

- Enter one of the following Selection Criteria:

No Group ID: To

import all data for that source that has no group ID. Use this option if

you specified a NULL group ID for this source.

All Group IDs: To

import all data for that source that has a group ID. Use this option to

import multiple journal batches for the same source with varying group

IDs.

Specific Group ID:

To import data for a specific source/group ID combination. Choose a

specific group ID from the List of Values for the Specific Value field.

If you do not

specify a Group ID, General Ledger imports all data from the specified

journal entry source, where the Group_ID is null.

- Define the Journal Import Run Options (optional)

Choose Post Errors

to Suspense if you have suspense posting enabled for your set of books

to post the difference resulting from any unbalanced journals to your

suspense account.

Choose Create Summary Journals to have journal import create the following:

• one journal line for all transactions that share the same account, period, and currency and that has a debit balance

• One journal line for all transactions that share the same account, period, and currency and that has a credit balance.

- Enter a Date Range to have General Ledger import only journals with accounting dates in that range. If you do not specify a date range, General Ledger imports all journals data.

- Choose whether to Import Descriptive Flexfields, and whether to import them with validation.

Click on Import button

Affected tables

GL_JE_BATCHES, GL_JE_HEADERS, GL_JE_LINES

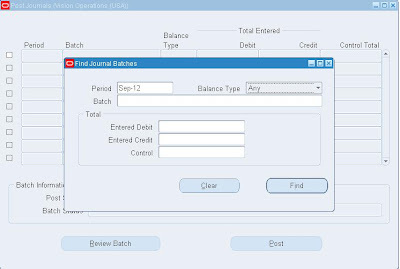

Posting:

We have to Post journal batches that we have imported previously to update the account balances in General Ledger

General Ledger> Journals > Enter

Click Find

From the list of unposted journals displayed, select one journal at a time and click on Post button to post the journal.

Ap supplier site update API in oracle apps

/* Formatted on 8/12/2015 12:49:32 PM (QP5 v5.240.12305.39446) */

DECLARE

l_vendor_site_rec AP_VENDOR_PUB_PKG.r_vendor_site_rec_type;

l_vendor_rec AP_VENDOR_PUB_PKG.r_vendor_rec_type;

x_vendor_site_id NUMBER;

x_vendor_id NUMBER;

x_msg_data VARCHAR2 (1000);

x_msg_count NUMBER;

p_count NUMBER;

x_return_status VARCHAR2 (10);

CURSOR lcu_rec

IS

SELECT vendor_id,

vendor_site_id,

purchasing_site_flag,

org_id

FROM ap_supplier_sites_all

WHERE vendor_site_id = 1136620;

BEGIN

FOR i IN lcu_rec

LOOP

l_vendor_site_rec.vendor_id := i.vendor_id; -- Supplier Id

l_vendor_site_rec.org_id := i.org_id; -- Operating Unit id

x_vendor_site_id := i.vendor_site_id; -- Site Id to be updated

-- l_vendor_site_rec.match_option := 'R';

l_vendor_site_rec.purchasing_site_flag := 'N'; -- eg: purchasing_site_flag

AP_VENDOR_PUB_PKG.Update_Vendor_Site (

p_api_version => 1,

x_return_status => x_return_status,

x_msg_count => x_msg_count,

x_msg_data => x_msg_data,

p_vendor_site_rec => l_vendor_site_rec,

p_vendor_site_id => x_vendor_site_id);

COMMIT;

END LOOP;

END;

DECLARE

l_vendor_site_rec AP_VENDOR_PUB_PKG.r_vendor_site_rec_type;

l_vendor_rec AP_VENDOR_PUB_PKG.r_vendor_rec_type;

x_vendor_site_id NUMBER;

x_vendor_id NUMBER;

x_msg_data VARCHAR2 (1000);

x_msg_count NUMBER;

p_count NUMBER;

x_return_status VARCHAR2 (10);

CURSOR lcu_rec

IS

SELECT vendor_id,

vendor_site_id,

purchasing_site_flag,

org_id

FROM ap_supplier_sites_all

WHERE vendor_site_id = 1136620;

BEGIN

FOR i IN lcu_rec

LOOP

l_vendor_site_rec.vendor_id := i.vendor_id; -- Supplier Id

l_vendor_site_rec.org_id := i.org_id; -- Operating Unit id

x_vendor_site_id := i.vendor_site_id; -- Site Id to be updated

-- l_vendor_site_rec.match_option := 'R';

l_vendor_site_rec.purchasing_site_flag := 'N'; -- eg: purchasing_site_flag

AP_VENDOR_PUB_PKG.Update_Vendor_Site (

p_api_version => 1,

x_return_status => x_return_status,

x_msg_count => x_msg_count,

x_msg_data => x_msg_data,

p_vendor_site_rec => l_vendor_site_rec,

p_vendor_site_id => x_vendor_site_id);

COMMIT;

END LOOP;

END;

Order to Cash full cycle and Techno-Functional flow in R12

The Order

to Cash Process flow starts with entering the order with a standard

item into system. When you enter an order, the item are validated in

oracle inventory, the price is calculated for the items using the

pricing engine; the availability of the items are checked and may be

reserved. Once all the required fields are entered on both the header

and the lines, you can book the order. When you click on the Book Order

button, the API OEXUBOKB.pls, checks if the order is eligible for

booking. If eligible the order is booked and the order header status

would change to booked. The next step is the pick release with which you

move the items from the warehouse to the staging area. The next step is

to ship confirm, to indicate that the items are loaded on to the

carrier from the staging area. When you run Ship Confirm, the system

decrements inventory and updates sales order line status. This

information is then transferred through the Auto Invoice to Account

Receivables for invoicing. Then you sent the invoice to your customer

for the items shipped and then perform the cash management and bank

reconciliations.

Order

Management receives detailed item information from the Inventory

application and price list information from the Pricing application.

Orders and returns can be entered manually or imported through an EDI,

CRM, or external source. Once in the system the order is ready to be

pick released and shipped, if needed by the Shipping application. It can

then proceed through the Auto Invoice program into the Oracle

Receivables application to be invoiced. All of the accounting

information is transferred to the General Ledger by the Inventory and

Receivables applications.

The

required fields to enter on the sales order header are the customer name

or number and order type. Other values such as Ship-To Address, Bill-To

Address, Shipping Method, and Price List default. The order number is

generated based on the order type. The required fields to enter on

the sales order lines are Ordered Item and Quantity. Again, based on

defaulting rules and setups in Pricing, Inventory and Shipping, the

other values would default on the sales order line.

Setup steps for executing the Order to Cash flow with a standard item:

· Prior

to order entry, the items should be created / defined in inventory

module using the master items screen and assigned to the shipping

organization. Check the blog post for the related setups

· Add the item to the price list or create a new price list.

· Transaction Type must be defined

· Document Sequence must be assigned to the document category.

· Customers must be defined

· Salespersons must be defined

· Shipping Roles should be granted to the user.

· Ensure that the items are available in your shipping sub inventory or perform miscellaneous transactions to augment the same.

Following are some useful related links:

Check the blog post for tables involved in various stages of O2C

Check the blog post on queries involved in Order management

Order to Cash flow with tables involved in various stages:

Order to Cash flow with statuses at various stages:

All possible flow statuses of the order/line:

• OE_ORDER_HEADERS_ALL.flow_status_code: Order Header (Entered) àBooked Order (Booked) à Closed Order (Closed)

• OE_ORDER_LINES_ALL.flow_status_code: Order Line (Entered) à Booked Order (Awaiting Shipping) à Pick Released(Picked/Staged) à Ship Confirmed (Shipped) à INV/OM interfaced (Fulfilled)à Close Order (Closed)

1. Enter the order header, line details and Book it:

Responsibility: Order Management Super User, Vision Operations (USA)

Navigate to Orders, Returns à Sales Orders

Open the Sales Orders Window

Order Number: 66413

Open the Sales Orders Window

Order Number: 66413

2. Schedule order:

· Check

if the order lines are scheduled or not. If any of the order line is in

BOOKED status, it means that the order line is not yet scheduled.

· Run the Schedule Order concurrent program to schedule the order. After the concurrent program is scheduled the order line will move to Awaiting Shipping status.

· Still if the order lines do not go to Awaiting Shipping, check for any holds on the order line/ header. Release the holds (if any) and re-run theSchedule Order program.

· You can even schedule the order line in the following way: Right click on the order line and progress the line to schedule it. Check the OM scheduling related setups

Order tables:

OE_ORDER_LINES_ALL.visible_demand_flag: visible_demand_flag= Yes lines will be made available as Demanded to Planning

Shipping tables: The shipping tables get populated after order scheduling.

WSH_DELIVERY_DETAILS.released_status: monitors the shipping process of the order line

WSH_DELIVERY_ASSIGNMENTS: Assigns delivery details to a delivery and/or a parent delivery detail.

Once the order is booked from the application, following changes occur in the backend

§ OE_ORDER_HEADERS_ALL (flow_status_code as BOOKED, booked_flag updated to Y)

§ OE_ORDER_LINES_ALL (flow_status_code as AWAITING_SHIPPING, booked_flag updated Y)

§ Since

the order is now booked, delivery details of the order are created in

WSH_DELIVERY_DETAILS table. WSH_DELIVERY_DETAILS has delivery lines and

LPNs.

OOL.line_id = WDD.source_line_id

§ These

delivery details information can been viewed form ‘Shipping

Transactions Form’ and the delivery status in the application will be as

‘Ready to Release’

§ WSH_DELIVERY_DETAILS.released_status =’R’

§ WSH_DELIVERY_DETAILS.Release_Status can have any of the below valid values

§ WSH_DELIVERY_ASSIGNMENTS (WDA) assigns delivery details to a delivery and/or a parent delivery detail (LPN).

WDA.delivery_detail_id = WDD.delivery_detail_id

§ WSH_DELIVERY_ASSIGNMENTS.delivery_id

will be NULL as still pick release operation is not performed as final

delivery is not yet created.

§ At

the same time when order is booked ‘Demand interface program’ is

triggered in the background and demand of the item with specified

quantity is created and these demand information is stored in

MTL_DEMAND.

MTL_DEMAND.demand_source_line = OOL.line_id

3. Pick Release the Sales Order

· Navigate to the Shipping Transaction Form (Shipping à Transactions)

Enter the following in the Query Manager window and click Find

From Order Number = 66413 To Order Number = 66413

· You can find the data in Shipping transaction screen (WSH shipping tables) only when order is scheduled.

· On the Shipping Transaction Form select Launch Pick Release from the Action menu and click on GO button.

· If

Auto Pick confirm is not selected while pick release, then we have to

manually do the transact move order process. In fact pick confirm also

triggers the transact move order process in which the inventory is moved

from item sub inventory to staging area.

Order line status becomes ‘Picked’ on Order and ‘Staged/Pick Confirmed’ on Shipping Form.

Order line status becomes ‘Picked’ on Order and ‘Staged/Pick Confirmed’ on Shipping Form.

§ MTL_MATERIAL_TRANSACTIONS_TEMP (Record gets deleted from here and gets posted to MTL_MATERIAL_TRANSACTIONS)

§ OE_ORDER_LINES_ALL.flow_status_code =’PICKED’

§ MTL_MATERIAL_TRANSACTIONS is updated with Sales Order Pick Transaction

MMT.trx_source_line_id = OOL.line_id

§ MTL_TRANSACTION_ACCOUNTS is updated with accounting information

§ WSH_DELIVERY_DETAILS. released_status=‘Y’ (‘Released’)

§ WSH_DELIVERY_ASSIGNMENTS, MTL_ONHAND_QUANTITIES are updated accordingly

Note:

Pick Confirm step can be eliminated if ‘Auto Pick Confirm’

is selected as ‘YES’ while performed manual pick release. If Pick

release is done through shipping transactions form and if you want to

perform auto pick confirm then picking rules setup has to be done.

4. Ship Confirm the Sales Order

· Navigate to the Shipping Transaction Form (Shipping à Transactions)

· Enter the following in the Query Manager window and click Find

From Order Number = 66413 To Order Number = 66413

· On

the Shipping Transaction Form navigate to the Delivery Tab and select

Ship Confirm from the Action menu and click on GO button. Ship

confirm process triggers the Interface Trip Stops concurrent program.

o OE_ORDER_LINES_ALL.flow_status_code =‘SHIPPED’

o WSH_DELIVERY_DETAILS. released_status=‘C’ (‘Shipped’)

o Data

from MTL_TRANSACTIONS_INTERFACE is moved to MTL_MATERIAL_TRANACTIONS

and MTL_MATERIAL_TRANSACTIONS is updated withSales Order Issue

transaction.

o Data is deleted from MTL_DEMAND, MTL_RESERVATIONS and WSH_NEW_DELIVERIES

o Item reduced from MTL_ONHAND_QUANTITIES

MTL_TRANSACTION_ACCOUNTS is updated with accounting information.

Following are the pick release status:

Table: WSH_DELIVERY_DETAILS

Column: RELEASED_STATUS

Possible Values:

B: Backordered- Line failed to be allocated in Inventory

C: Shipped -Line has been shipped

D: Cancelled -Line is Cancelled

N: Not Ready for Release -Line is not ready to be released

R: Ready to Release: Line is ready to be released

S: Released to Warehouse: Line has been released to Inventory for processing

X: Not Applicable- Line is not applicable for Pick Release

Y: Staged- Line has been picked and staged by Inventory

C: Shipped -Line has been shipped

D: Cancelled -Line is Cancelled

N: Not Ready for Release -Line is not ready to be released

R: Ready to Release: Line is ready to be released

S: Released to Warehouse: Line has been released to Inventory for processing

X: Not Applicable- Line is not applicable for Pick Release

Y: Staged- Line has been picked and staged by Inventory

Check the blog post for the detailed pick release status

· Verify the details on the Confirm Delivery window and click OK and close the window.

5. Run the Interface Trip Stop – SRS Program

· The

Interface Trip Stop (ITS) will be trigger at the time of Shipping if

check box “Defer Interface” is not check. ITS can also be executed from

concurrent request.

Interface Trip Stop has two main components:

Interface Trip Stop has two main components:

1. Update the Order Management Data (oe_order_lines_all)

2. Trigger the Inventory Interface (to Update the Inventory tables)

· ITS updates the following fields on oe_order_lines_all table:

· Shipped_quantity

· Shipping_quantity

· Actual_shipment_date

· Inventory

Interface will be trigger only if the first part, that means related to

OM has successfully completed and flag OE_INTERFACED_FLAG = ‘Y’ on

WSH_DELIVERY_DETAILS. If value of this flag is N/P then Inventory

Interface will never be triggered. And even if you try to submit the

Inventory Interface from SRS, delivery detail with oe_interfaced_flag

=’N’ will never be picked up.

o oe_interfaced_flag = Y -- signifies ITS has interfaced shipping data to OM

o inv_interfaced_flag = Y -- signifies ITS has interfaced shipping data to INV

Navigate to Shipping Interfaces window (Shipping à Interfaces à Run)

Select the Interface Trip Stop - SRS Program from the LOVs

On the parameters window enter

Mode = All

Click on the OK button and then on the Submit button:

6. Run the Master AutoInvoice Program

Navigate to the Run AutoInvoice window, (Interfaces à AutoInvoice)

Select the AutoInvoice Master Program from the LOV

On the parameters window enter

Invoice Source = ORDER ENTRY

Default Date = Enter Today’s Date

(Low) Sales Order Number = 66413

(High) Sales Order Number = 66413

Then click OK and Submit button.

7. View the Transaction created by the AutoInvoice Program

· Navigate to the Additional Line Information window, (Orders, Returns àOrder Organizer)

· On the Find Order window, query your order number = 66413

· On

the Order Organizer window, navigate to Lines Tab and click on Actions

button and select the Additional Line information and click OK.

8. On

the Additional Line Information window, navigate to Invoices / Credit

Memos Tab and click on the Invoice Details button. This would open

Transactions window, where you can see the invoice details.

Following is an important Query which gives the joining between OM, WSH, AR Tables

SELECT ooh.order_number

,ool.line_id

,ool.ordered_quantity

,ool.shipped_quantity

,ool.invoiced_quantity

,wdd.delivery_detail_id

,wnd.delivery_id

,rctl.interface_line_attribute1

,rctl.interface_line_attribute3

,rctl.interface_line_attribute6

,rct.org_id

,rct.creation_date

,trx_number

,rctl.quantity_ordered

,rct.interface_header_context

FROM oe_order_headers_all ooh

,oe_order_lines_all ool

,wsh_delivery_details wdd

,wsh_new_deliveries wnd

,wsh_delivery_assignments wda

,ra_customer_trx_all rct

,ra_customer_trx_lines_all rctl

WHERE ooh.header_Id=ool.header_id

AND wdd.source_header_id=ooh.header_id

AND wdd.delivery_detail_Id=wda.delivery_detail_id

AND wda.delivery_id=wnd.delivery_id

AND rctl.interface_line_attribute1=to_char(ooh.order_number)

AND rctl.interface_line_attribute6=to_char(ool.line_id)

AND rctl.interface_line_attribute3=to_char(wnd.delivery_id)

AND rctl.customer_trx_id=rct.customer_trx_id

AND rct.interface_header_context='ORDER ENTRY'

O2C: Accounting Entries:

Transaction Event

|

Debit

|

Credit

|

Module

|

Enter Sales Order

|

No Accounting Entry

|

Order Mgmt

| |

Book Order

| |||

Pick Release Order

| |||

Ship goods to customer

|

Cost of Goods Sold a/c

|

Inventory a/c

|

Inventory

|

Issue Invoice

|

Receivables a/c

|

Revenue a/c

|

Receivables

|

Collecting Payment

|

Cash/Bank a/c

|

Receivables a/c

|

Receivables

|

Subscribe to:

Comments (Atom)